Why dead horizontal lines are harder to fix…

July 21st, 2011There’s a (relatively) well-known method of fixing dead lines on the DMG-01 (classic Gameboy) LCD screen which consists of dragging a hot soldering iron across the connection of the brown plastic connector with an epoxy blob, and the glass. The right spot in underneath where there’s normally a black rubber strip. This will reflow the glue, solder or whatever is used for the attachment, and the method can usually successfully fix dead vertical lines.

Sometimes people ask whether horizontal lines can be fixed as well. I’ve always assumed that the connector on the right side of the screen, which would be at fault if there are dead vertical lines, is basically identical, and that the only problem with fixing horizontal lines is the more awkward position of the connection — the “ribbon” is connected on the bottom side of the LCD glass, so you need to fit the soldering iron into a small corner without damaging anything.

However, the ribbon connector on the right side is different and more fragile. If you look at the top image, you’ll see a connector that looks brown. Technically speaking, this is called a flexible PCB (printed circuit board.) Just like on a regular, rigid PCB — like the display daughterboard itself — you have copper traces for connections and a green solder mask. The black blob in the middle is an integrated circuit, not unlike the chips you would see on any other circuit board, only that this one is hidden within a blob made of epoxy, and the circuit on the chip is connected directly to the copper traces, rather than using external pins soldered to a circuit board.

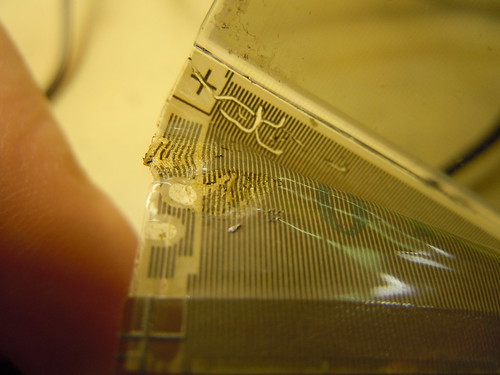

The right side connector has a similar flexible PCB, but the last stretch of the connection is made by a flimsy white plastic material which is easily damaged by the heat from a soldering iron. The actual connectors are not made of copper but possibly carbon or some other conductive material. My advice is, do not try to fix dead horizontal lines. You’ll likely just mess up the connector as seen below.

![You suck at protoshop. No, you [i]really[/i] oo.](http://blog.gg8.se/images/you-suck-at-photoshop-you-really-do-your-awful.png)

May 16th, 2012 at 2:36 pm

Horizontal lines suck when they go out. I had 3 out near the top, but earlier today I was going to install a backlight and over ten went out. It sucks because I just put over $50 into the gameboy that was near perfect condition and probably won’t be able to use it. I really hate to ask, but does Anyone have a spare DGM that they wouldn’t mind selling?

March 22nd, 2013 at 3:09 am

Hi

I’ve stumbled across your site by simply googling “attaching ribbon to lcd glass”, and now that I see the work you are doing here, I have an advice that may help you with this white ribbon cable: It is a special cable indeed, and not of the same type as the brown one. I have successfully repaired dead lines on LCD displays in some devices, including my collection of vintage Motorola StarTAC GSM phones, for which the LCD modules are no longer available anywhere.

The trick in “resoldering” this type of ribbon without damaging it, is using an iron with temperature control. The bonding material on those cables melts at 190 degrees Celcius, and I had good success reflowing the glue when I set my Weller soldering station to 205 degrees. Simple soldering irons without temperature control heat up to more than 300 degrees, and this will destroy the cable by completely melting it, when I first tried doing this with a regular iron I had the same results as you are showing here.

Anyway, I won’t be digging into the subject here, but if you would like more info or any tips, feel free to send me an email, I would be glad to help.

Take care.

March 22nd, 2013 at 3:15 am

Also, looking at the last picture again, it is much more likely that the connection of the ribbon is problematic on the end that attaches to the green flexible PCB rhather than the LCD end. If you’ll look closely, you’ll notice that each trace on the white ribbon has irregularities and is not smooth on the PCB end, while on the LCD end the traces look smooth where it is attached to the glass.

In those StarTAC’s I’ve mentioned, the problematic connection was always on the PCB end, and the traces looked just like in your picture here.

February 6th, 2014 at 9:07 am

Thanks for putting this here! It looks like a real pain to try and fix the connections to correct the horizontal line problem. Maybe I’ll give it a try once I have a temperature controlled soldering iron thanks to crow’s input. Thanks to this I won’t ruin my front board completely by using the iron I have now.

March 20th, 2014 at 8:01 am

One offshore pcb manufacture seeking for cooperation

June 11th, 2015 at 5:16 pm

Hello Nintendo fans, If anyone out there that’s having Horizontal dead lines on there Game Boy Compact Original or any other Game Boy Console & want it back to full working order, we do repairs on them. We are Experience repairer in both Vertical & Horizontal lines. We only charge $1 each a column in vertical lines to repair & $2 each a column in Horizontal lines to repair. They do come back with a 12 months warranty towards any repairs we do on them. Just check out our website & what repairs we do. If you have any question, please contact us on our website & we will get back to you asap. Thank you.

April 19th, 2016 at 4:42 am

Hey Mark,

I have dead horizontal lines!!! Some bastard traded a rare game of mine for this gameboy (what I though, a good trade). Turns out the very top portion of the screen is all dead lines. It was near impossible to tell at first glance because it blended well with the rest. I have another problem, I am in the U.S. Shipping to Australia would not be worth it to me. It would probably be cheaper to just buy another gameboy. I was wondering if you could just pass some advice for fixing horizontal deadlines. It would be very much appreciated.

Thank you,

Justin

September 7th, 2016 at 2:17 pm

Hi

Is there anything new about if the horizontal lines can befixed ?

September 17th, 2016 at 2:38 am

Crow nailed it! I had horizontal lines on my GB pocket and I turned down the heat to 180 and put flux on the ribbon cable. 2 passes and everything looks great!

Thanks Crow!!!

December 8th, 2017 at 7:54 pm

Hi Mark

What is your website? I am in Spain.

Will it be very difficult to send it to you so that you repair it?

January 16th, 2018 at 1:08 pm

Yes the horizontal lines can be fixed on an original gameboy but you need an soldering iron with temperature control settings and keep it under 190 degrees then. But diagital lines can not be fixed at all unless you replace the screen then. Original gameboy.

January 16th, 2018 at 1:13 pm

The capacitors in original gameboy can have the liquid paste in them that can dry out and if you original gameboy red power light does off after the Nintendo logo comes down the screen and no game pack inserted and it makes a ding or a beep noise after. They can go bad because the have a liquid paste that can dry out and can turn into a resistors and that can eventually kill an original gameboy or use up excessive battery power from the batteries.

January 16th, 2018 at 1:16 pm

To replace the capacitors for an original gameboy can be very hard and tricky to do you need a original gameboy cap kits then. Not recommended for inexperienced people and you need a soldering iron with temperature control settings. Safety googles needed and gloves and something to cover your mouth as they can produce a toxic odor that can cause health problems.

June 5th, 2018 at 7:23 pm

i have that same gameboy. but it is odd. my screen have 3 Horizontal lines and i checked inside it is fine no damage???

i already fixed battery connecters but one is battery connecter is tarnished and can it be cleaned and fixed?

June 5th, 2018 at 7:24 pm

oh i forget. i meant battery connecter IS attached to motherboard.

March 26th, 2019 at 2:38 pm

[...] Why dead horizontal lines are harder to fix… [...]